|

PROGRAMMING SUGGESTIONS • Form tools should be the last operation punched. • As a form die is higher than a standard die, try not to program the use of either station adjacent to the form. • With today’s fast CNC presses, it is helpful to program a pause or dwell after each hit from a form tool. This gives extra time for the sheet to be stripped off of the tool. Further, if available program a slow stroke speed. |

|

NEXT PAGE |

|

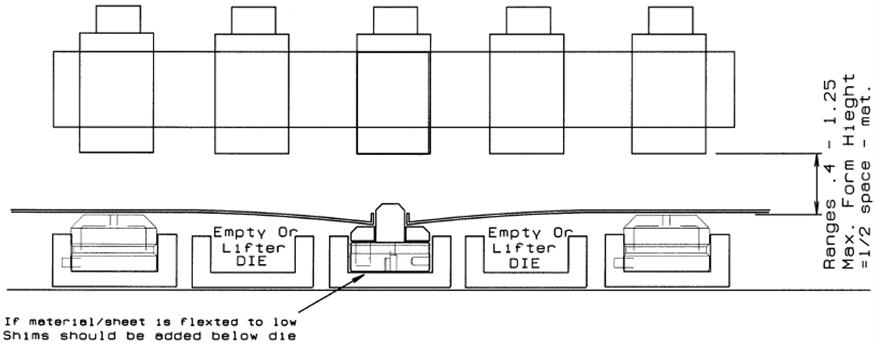

FORM REQUIRING LARGE STROKE (Deep Stroke) |

|

Diagram shows sheet movement below standard die height. Form requiring deep stroke will require sheet to be moved below standard die height. No dies should be left installed in stations to left & right of such form dies. Ideally lifter dies should be installed either side of form. |

|

Lifter dies are placed in your turret on each side of a special forming tool. When the sheet passes through this section of the turret, these lifter dies will lift the sheet up above that of a standard die. This will help guide sheet to the height of a tall forming die preventing an abrupt jerking action when sheet meets form die which at times causes the sheet to break the grip of the work holder clamps. |

|

Sheet Lifter Dies |

|

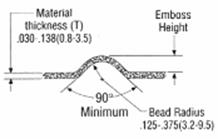

Program any shape, of a raised emboss, from circular to straight lines. Form up to .25”/6,4mm height, in material up to 2mm thick. Nibble moves of .03”/,8mm |

|

Example PROGRESSIVE BEADING |

|

Programming Progressive-Continues Forms such as Louvers, Card Guides, Stiffening Ribs Start in center, nibbling to one side in .8mm/.03” increments. Next move back to center and nibble back to other side. If needed make single hit in center. |

|

Example PROGRESSIVE STIFENING RIB |