|

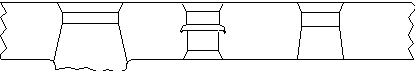

Determining Die Clearances In order to receive optimum performance from a punch and die, it is necessary that the proper clearance be provided in the die in accordance with the material to be punched (pierced). Hole quality (edge roll, and burr), tool life, and slug pulling are results from die clearance. •Excessive clearance, although achieves longer tool life, will leave more burr, and leads to slug pulling problems. • Insufficient clearance will leave little to no burr, but lessen tool life, and can cause a secondary break . Note: Increasing die clearance when holes are close to edge of sheet will minimize distortion of sheet edge. EXCESSIVE INSUFFICIENT PROPER CLEARANCE CLEARANCE CLEARANCE

|

|

There are many factors that may change the optimum clearance value. RIGIDITY OF PRESS, MATERIAL GRADE, SPEED OF STROKE |

|

Back to Technical Ref. Index |

|

|

|

CE TOOLING Clearance Chart |

|

RETURN TO TECHNICAL INDEX |

|

NEXT PAGE |

|

Type of Material |

% of Material |

||

|

Min |

Best |

Max |

|

|

Aluminum, Soft |

5 |

10 |

15 |

|

Brass, 1/2 Hard |

6 |

11 |

16 |

|

Copper, 1/2 Hard |

8 |

12 |

16 |

|

CRS-Mild Steel/Galvanize |

10 |

15 |

20 |

|

Steel D.50C |

12 |

18 |

24 |

|

Stainless Steel |

15 |

22 |

30 |

|

Matt. Thickness X % = Clearance |

|||

|

MATERIAL |

MILD STEEL CRS/HRS 15% |

ALUMINUM (SOFT) 10% |

STAINLESS STEEL 22% |

BRASS 11% 1/2 HARD |

COPPER 12% 1/2 HARD |

STEEL .50 C 18% |

||||||||

|

INCH” |

MM |

Gauge |

INCH” |

MM |

INCH” |

MM |

INCH” |

MM |

INCH” |

MM |

INCH” |

MM |

INCH” |

MM |

|

.010 |

,25 |

32 |

.0015 |

,03 |

.0015 |

,03 |

.002 |

,05 |

.0015 |

,03 |

.0015 |

,03 |

.002 |

,05 |

|

.015 |

,38 |

28 |

.0025 |

,06 |

.0015 |

,03 |

.003 |

,08 |

.002 |

,05 |

.002 |

,05 |

.003 |

,08 |

|

.018 |

,45 |

26 |

.003 |

,08 |

.002 |

,05 |

.004 |

,09 |

.002 |

,05 |

.0025 |

,06 |

.004 |

,09 |

|

.024 |

,60 |

24 |

.004 |

,10 |

.003 |

,06 |

.005 |

,13 |

.003 |

,08 |

.003 |

,03 |

.003 |

,03 |

|

.030 |

,76 |

22 |

.005 |

,11 |

.003 |

,08 |

.007 |

,17 |

.0035 |

,09 |

.004 |

,10 |

.006 |

,14 |

|

.036 |

,91 |

20 |

.006 |

,14 |

.004 |

,10 |

.008 |

,20 |

.004 |

,10 |

.005 |

,11 |

.007 |

,17 |

|

.048 |

1,2 |

18 |

.007 |

,18 |

.005 |

,13 |

.010 |

,27 |

.006 |

,14 |

.006 |

,15 |

.009 |

,22 |

|

.054 |

1,4 |

17 |

.008 |

,20 |

.006 |

,14 |

.012 |

,30 |

.006 |

,15 |

.007 |

,17 |

.010 |

,25 |

|

.062 |

1,6 |

16 |

.009 |

,23 |

.006 |

,15 |

.014 |

,35 |

.007 |

,18 |

.008 |

,20 |

.011 |

,30 |

|

.067 |

1,7 |

15 |

.010 |

,25 |

.007 |

,18 |

.015 |

,37 |

.008 |

,19 |

.008 |

,20 |

.012 |

,30 |

|

.075 |

1,9 |

14 |

.011 |

,28 |

.008 |

,19 |

.017 |

,42 |

.008 |

,22 |

.009 |

,23 |

.014 |

,35 |

|

.090 |

2,3 |

13 |

.014 |

,34 |

.009 |

,23 |

.020 |

,50 |

.010 |

,25 |

.011 |

,30 |

.015 |

,40 |

|

.105 |

2,7 |

12 |

.016 |

,40 |

.011 |

,27 |

.023 |

,60 |

.012 |

,30 |

.015 |

,38 |

.029 |

,56 |

|

.120 |

3,1 |

11 |

.018 |

,46 |

.012 |

,30 |

.026 |

,70 |

.013 |

,33 |

.016 |

,40 |

.024 |

,62 |

|

.135 |

3,4 |

10 |

.020 |

,51 |

.014 |

,34 |

.030 |

,75 |

.015 |

,38 |

.018 |

,46 |

.027 |

,70 |

|

.150 |

3,8 |

9 |

.023 |

,57 |

.015 |

,38 |

.033 |

,85 |

.017 |

,42 |

.020 |

,50 |

.025 |

,60 |

|

.164 |

4,2 |

8 |

.025 |

,60 |

.017 |

,42 |

.036 |

,90 |

.018 |

,46 |

.021 |

,55 |

.032 |

,80 |

|

.179 |

4,6 |

7 |

.027 |

,68 |

.018 |

,46 |

.039 |

1,0 |

.020 |

,50 |

.023 |

,60 |

.035 |

,90 |

|

.194 |

5,0 |

6 |

.029 |

,70 |

.020 |

,50 |

.043 |

1,1 |

.021 |

,54 |

.025 |

,65 |

.038 |

,95 |

|

.209 |

5,3 |

5 |

.031 |

,80 |

.021 |

,55 |

.046 |

1,2 |

.023 |

,58 |

.027 |

,70 |

.040 |

1,0 |

|

.239 |

6,1 |

3 |

.036 |

,91 |

.024 |

,60 |

.053 |

1,4 |

.026 |

,70 |

.029 |

,75 |

.043 |

1,1 |

|

.250 |

6,4 |

1/4 |

.038 |

,95 |

.025 |

,60 |

.055 |

1,4 |

.028 |

,70 |

.030 |

,76 |

.045 |

1,2 |

|

.312 |

8 |

5/16 |

.048 |

1,2 |

.031 |

,79 |

.070 |

1,8 |

.035 |

,89 |

.038 |

1,0 |

.056 |

1,5 |

|

.375 |

9,5 |

3/8 |

.056 |

1,4 |

.037 |

1,0 |

.082 |

2,1 |

.041 |

1,1 |

.045 |

1,2 |

.068 |

1,8 |

|

.500 |

12,7 |

1/2 |

.075 |

1,9 |

.050 |

1,3 |

.120 |

2,8 |

.055 |

1,4 |

.060 |

1,5 |

.090 |

2,3 |