|

Sheet Lifter Dies Lifter dies are placed in your turret press on each side of a special forming tool. When the sheet passes through this section of the turret, these lifter dies will lift the sheet up to the height of the form die preventing the sheet from colliding with the forming die, which at times, can cause the sheet to break the grip of the work holder clamps.

|

|

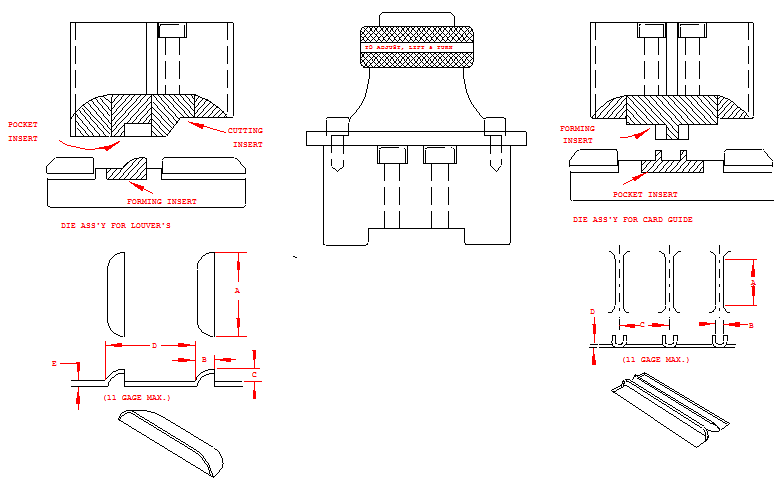

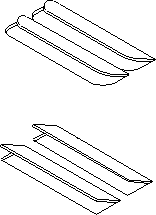

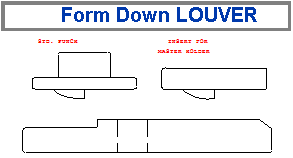

LOUVERS AND CARD-GUIDES Unlike standard single hit tool, Progressive allows form to be nibbled to unlimited lengths. The smaller the nibble, the more attractive the form. Nibble range=.025-.75 Expect a small blemish were nibbling starts. Progressive tools are made to exact material thickness, were standard louvers can punch a range of material thickness. Progressive louver must have gentle radius slope on end, were standard louver can be tight radius. |

|

STANDARD OR PROGRESSIVE |

|

In designing a lance, watch that lower form cutting insert can extend far enough through material to support 100% of requested height. Maximum height is 1/4 on most tool styles. |

|

Open-Rad. End w/No Mat. Been Lances: Another option to having <3xMat. F-to-B is to leave no material between. To do this, Radius corners are required. The material left In this radius area is were material is twisted from. Form Height: Lower insert, cutting edge must cutting insert must have min. of .03 radius |

|

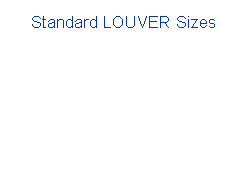

A Length |

B |

C |

D |

|

2 2-1/2 |

1/2 |

3/16 |

3/4 |

|

3 3-1/2 |

5/8 |

1/4 |

15/16 |

|

4 4-1/2 |

3/4 |

1/4 |

1-1/8 |

|

RETURN TO FORMS DIRECTORY |

|

|

|

CE TOOLING Louver & Card Guide |