|

Material T → |

#22 .03” |

#20 .036 |

#18 .048 |

#16 .06 |

#14 .075 |

#13 .09 |

Extrusion B Ø cut Thread |

Recommended ↓ Pre-Pierce |

|

↓screw |

↓ Female Bore Dimension ↓ |

|||||||

|

#4-40 |

.127 |

.136 |

|

|

|

|

.090 |

.045 |

|

#5-40 |

.139 |

.148 |

.165 |

.180 |

|

|

.102 |

.051 |

|

#6-32 |

.144 |

.153 |

.171 |

.185 |

|

|

.107 |

.053 |

|

#8-32 |

|

.182 |

.199 |

.214 |

.233 |

|

.136 |

.064 |

|

#10-24 |

|

|

.213 |

.228 |

.247 |

.267 |

.150 |

.069 |

|

#10-32 |

|

|

.222 |

.237 |

.256 |

.276 |

.159 |

.074 |

|

1/4-20 |

|

|

.268 |

.283 |

.302 |

.322 |

.205 |

.100 |

|

1/4-28 |

|

|

|

|

|

|

|

|

|

RETURN TO FORMS DIRECTORY |

|

NEXT PAGE |

|

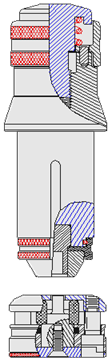

ELECTRICAL KNOCK OUT TOOLS |

|

|

|

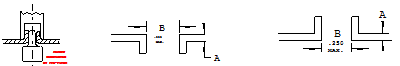

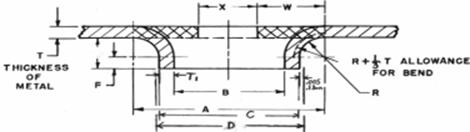

CE TOOLING Extrusions |

|

Extrusions our commonly used to accept sheet metal screws or permit tapping into a deeper distance than just the material thickness. A pre-punched hole is required as a one hit pierce and extrude gives poor hole quality, and has limited adjustment on the machine. The diameter of the pre-punched hole ultimately determines the height of the extrusion. The limitation to the height is simply the metal’s limit of being drawn (stretched).

Below is formula for determining pre-pierce “X” hole size |

|

Reference Info: X=Pierce Ø B=Max. ExtrusionØ C= B + 2(T1) D= C + .010” T=Mat’l Thickness H-Nominal Extrusion Hgt. T1=Min. Mat’l Thk –.002” Nominal H is 2 to 2½ of T Formula for determining X if specific H is required X=D- 3.14(.005+.25T)-2(H-.005) |

|

Material: T → |

#22 .03” |

#20 .036 |

#18 .048 |

#16 .06 |

#14 .075 |

#13 .09 |

Extrusion B Ø Cut Thread |

Recommended ↓ Pre-Pierce |

|

↓screw |

↓ Female Bore Dimension ↓ |

|||||||

|

M2,X,4 |

2,74 |

3,0 |

3,26 |

3,78 |

|

|

1,7 |

0,8 |

|

2,5x4,5 |

3,14 |

3,4 |

3,66 |

4,18 |

|

|

2,1 |

1,0 |

|

M3,X,5 |

3,64 |

3,9 |

4,16 |

4,68 |

|

|

2,6 |

1,3 |

|

M4,X,7 |

|

4,7 |

4,96 |

5,48 |

6,0 |

6,39 |

3,4 |

1,6 |

|

M5,X,8 |

|

|

5,86 |

6,38 |

6,9 |

7,29 |

4,3 |

2,0 |

|

M6,X1, |

|

|

6,66 |

7,18 |

7,7 |

8,09 |

5,1 |

2,5 |